- STRANDING & RESISTANCE CHART

- SOFTWOOD DRUM SIZES

- PLYWOOD REEL SIZES

- COMPOUND & FEATURES CHART

- AWG mm² CONVERSION TABLE

KEY:

To BS6360, IEC 60228 and VDE 0295.

Class 1 & 2: Shows the required number of strands.

Class 5 & 6: Shows the maximum strand diameter, may be fewer strands as long as the maximum ohms/km is not exceeded.

Ohms Ω/km: Shows the maximum resistance permissible for untinned copper conductors in the stranding classes indicated.

| Area (mm²) | Stranding Class 1 | Stranding Class 2 | Ohms Ω/km | Stranding Class 5 | Stranding Class 6 | Stranding Class 6 |

|---|---|---|---|---|---|---|

| 0.14 | N/A | N/A | N/A | 18 x 0.10 | 18 x 0.10 | 138.0 |

| 0.25 | N/A | N/A | N/A | 14 x 0.16 | 32 x 0.10 | 79.0 |

| 0.34 | N/A | N/A | N/A | 19 x 0.16 | 42 x 0.10 | 57.0 |

| 0.5 | 1 x 0.80 | 7 x 0.30 | 36.0 | 16 x 0.21 | 28 x 0.10 | 39.0 |

| 0.75 | 1 x 0.97 | 7 x 0.37 | 24.5 | 24 x 0.21 | 42 x 0.16 | 26.0 |

| 1.0 | 1 x 1.13 | 7 x 0.43 | 18.1 | 32 x 0.21 | 56 x 0.16 | 19.5 |

| 1.5 | 1 x 1.38 | 7 x 0.53 | 12.1 | 30 x 0.26 | 84 x 0.16 | 13.3 |

| 2.5 | 1 x 1.78 | 7 x 0.67 | 7.41 | 50 x 0.26 | 140 x 0.16 | 7.98 |

| 4.0 | 1 x 2.26 | 7 x 0.85 | 4.61 | 56 x 0.31 | 224 x 0.16 | 4.95 |

| 6.0 | 1 x 2.76 | 7 x 1.04 | 3.08 | 84 x 0.31 | 192 x 0.21 | 3.30 |

| 10.0 | 1 x 3.57 | 7 x 1.35 | 1.83 | 80 x 0.41 | 320 x 0.21 | 1.91 |

| 16.0 | 1 x 4.51 | 7 x 1.70 | 1.15 | 128 x 0.41 | 512 x 0.21 | 1.21 |

| 25.0 | N/A | 7 x 2.14 | 0.72 | 200 x 0.41 | 800 x 0.21 | 0.78 |

| 35.0 | N/A | 7 x 2.52 | 0.524 | 280 x 0.41 | 1120 x 0.21 | 0.554 |

| 50.0 | N/A | 19 x 1.78 | 0.387 | 400 x 0.41 | 705 x 0.31 | 0.386 |

| 70.0 | N/A | 19 x 2.14 | 0.268 | 356 x 0.51 | 990 x 0.31 | 0.272 |

| 95.0 | N/A | 19 x 2.52 | 0.193 | 485 x 0.51 | 1340 x 0.31 | 0.206 |

| 120 | N/A | 37 x 2.03 | 0.153 | 614 x 0.51 | 1690 x 0.31 | 0.161 |

| 150 | N/A | 37 x 2.25 | 0.124 | 765 x 0.51 | 2123 x 0.31 | 0.129 |

| 185 | N/A | 37 x 2.52 | 0.099 | 944 x 0.51 | 1470 x 0.41 | 0.106 |

| 240 | N/A | 61 x 2.25 | 0.074 | 1225 x 0.5 | 1905 x 0.41 | 0.081 |

KEY:

Softwood drums can be treated and stamped for export.

Standard centre hole is 83mm.

Qty Per Load: The maximum number of cable drums per load (40ft articulated lorry trailer).

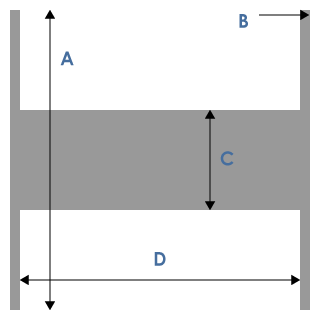

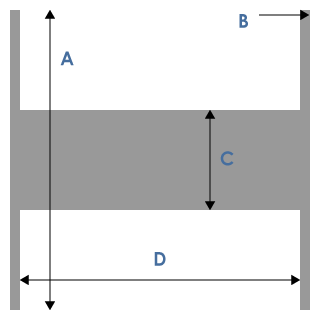

Description: A (flange diameter) x B (flange width) x C (barrel diameter) x D (traverse).

| Description (mm) | Flange Width (mm) | Barrel Lag Width (mm) | Steel Rods x Width (mm) | Cross Struts | Steel Plate (mm) | Qty Per Load | Tare Weight |

|---|---|---|---|---|---|---|---|

| 500 x 38 x 250 x 250 | 38 | 19 | 3 x 10 | No | No | 450 | 9Kg |

| 600 x 38 x 300 x 300 | 38 | 19 | 4 x 10 | No | No | 350 | 13Kg |

| 750 x 44 x 400 x 400 | 44 | 22 | 4 x 10 | No | No | 240 | 24Kg |

| 800 x 44 x 400 x 400 | 44 | 22 | 4 x 10 | No | No | 200 | 34Kg |

| 900 x 44 x 450 x 450 | 44 | 22 | 4 x 10 | No | No | 150 | 43Kg |

| 1000 x 44 x 500 x 500 | 44 | 22 | 4 x 10 | No | No | 113 | 45Kg |

| 1200 x 44 x 600 x 600 | 44 | 22 | 4 x 10 | No | No | 85 | 64Kg |

| 1400 x 50 x 700 x 700 | 50 | 25 | 4 x 12 | No | No | 42 | 103Kg |

| 1500 x 50 x 900 x 700 | 50 | 25 | 4 x 12 | No | No | 38 | 129Kg |

| 1600 x 64 x 1000 x 800 | 64 | 32 | 6 x 16 | Yes | 200 x 200 | 34 | 190Kg |

| 1700 x 64 x 1000 x 800 | 64 | 32 | 6 x 16 | Yes | 200 x 200 | 34 | 214Kg |

| 1800 x 64 x 1000 x 800 | 64 | 32 | 6 x 16 | Yes | 200 x 200 | 20 | 224Kg |

| 2000 x 64 x 1000 x 800 | 64 | 32 | 6 x 16 | Yes | 200 x 200 | 16 | 327Kg |

| 2200 x 76 x 1200 x 800 | 76 | 38 | 6 x 16 | Yes | 200 x 200 | 14 | 475Kg |

KEY:

Standard centre hole is 83mm.

Description: A (flange diameter) x B (flange width) x C (barrel diameter) x D (traverse).

| Description (mm) | Flange Width (mm) | Flange Diameter (mm) | Barrel Diameter (mm) | Traverse (mm) | Construction | Qty Per Pallet |

|---|---|---|---|---|---|---|

| 200 x 100 x 100 | 6 | 200 | 100 | 100 | MSR | 420 |

| 200 x 100 x 150 | 6 | 200 | 100 | 150 | MSR | 250 |

| 225 x 100 x 100 | 6 | 225 | 100 | 100 | MSR | 420 |

| 225 x 100 x 150 | 6 | 225 | 100 | 150 | MSR | 250 |

| 250 x 100 x 100 | 6 | 250 | 100 | 100 | MSR | 300 |

| 250 x 100 x 150 | 6 | 250 | 100 | 150 | MSR | 180 |

| 275 x 100 x 100 | 6 | 275 | 100 | 100 | MSR | 300 |

| 275 x 100 x 150 | 6 | 275 | 100 | 150 | MSR | 180 |

| 300 x 100 x 150 | 6 | 300 | 100 | 150 | MSR | 120 |

| 300 x 150 x 150 | 6 | 300 | 150 | 150 | MSR | 120 |

| 325 x 100 x 150 | 6 | 325 | 100 | 150 | MSR | 120 |

| 325 x 150 x 150 | 6 | 325 | 150 | 150 | MSR | 120 |

| 350 x 100 x 150 | 6 | 350 | 100 | 150 | MSR | 120 |

| 350 x 150 x 150 | 6 | 350 | 150 | 150 | MSR | 96 |

| 400 x 200 x 200 | 6 | 400 | 200 | 200 | TUBE | 81 |

| 400 x 200 x 200 | 8 | 400 | 200 | 200 | TUBE | 81 |

| 450 x 200 x 200 | 6 | 450 | 200 | 200 | TUBE | 81 |

| 450 x 200 x 200 | 8 | 450 | 200 | 200 | TUBE | 81 |

| 500 x 200 x 200 | 8 | 500 | 200 | 200 | TUBE | 81 |

| 500 x 250 x 250 | 8 | 500 | 250 | 250 | TUBE | 63 |

| 600 x 300 x 300 | 8 | 600 | 300 | 300 | TUBE | 36 |

| 600 x 300 x 300 | 12 | 600 | 300 | 300 | TUBE | 36 |

| 700 x 350 x 350 | 8 | 700 | 350 | 350 | TUBE | 20 |

| 700 x 350 x 350 | 12 | 700 | 350 | 350 | TUBE | 20 |

| 750 x 350 x 350 | 8 | 750 | 350 | 350 | TUBE | 20 |

| 750 x 350 x 350 | 12 | 750 | 350 | 350 | TUBE | 20 |

| 800 x 400 x 400 | 12 | 800 | 400 | 400 | TUBE | 20 |

| 800 x 450 x 450 | 12 | 800 | 450 | 450 | TUBE | 16 |

| 850 x 400 x 400 | 12 | 850 | 400 | 400 | TUBE | 16 |

| 850 x 450 x 450 | 12 | 850 | 450 | 450 | TUBE | 16 |

| 900 x 450 x 450 | 12 | 900 | 450 | 450 | TUBE | 8 |

| 900 x 450 x 450 | 15 | 900 | 450 | 450 | TUBE | 8 |

KEY:

X = Poor

XX = Fair

XXX = Good

XXXX = Very Good

XXXXX = Excellent

| Compound | Compound Code | Working Temp. °C | Water Resistance | Oil / Grease Resistance | Solvents Resistance | Alcohol Resistance |

|---|---|---|---|---|---|---|

| Polyvinyl Chloride | PVC | -30/60 +105 | XXX | XX | X | XXX |

| Flexible Polyvinyl Chloride | PVC S-N | -10 +80 | XXX | XX | X | XX |

| Polyvinyl Chloride Nitrile | PVC NBR | -30 +80 | XXX | XXXX | XX | XXX |

| Polyethylene LD | LDPE | -50 +70 | XXXXX | XX | X | XXXX |

| Polyethylene HD | HDPE | -50 +100 | XXXXX | XX | X | XXXX |

| Cellular Polyethylene | PES | -50 +70 | XXXXX | XX | X | XXXX |

| Polyamide | PA | -70 +120 | X | XXXXX | XXX | X |

| Polyurethane Polyester | PUR | -50 +90 | X | XXXXX | XXX | XX |

| Polyurethane Polyether | PUR | -50 +90 | XXXX | XXXXX | XXXX | XX |

| Perfluoroalkoxy | PFA | -180 +250 | XXXX | XXXX | XXXX | XXXX |

| Ethylene Tetrafluoroethylene | ETFE | -100 +150 | XXXX | XXXX | XXXX | XXX |

| Polytetrafluoroethylene | PTFE | -180 +250 | XXXXX | XXXX | XXXX | XXXX |

| Perfluoroethylenpropylene | FEP | -100 +200 | XXXXX | XXXX | XXXX | XXXX |

| Polypropylene | PP | -30 +100 | XXXX | XXXX | XX | XXXX |

| Polyvinylidene Fluoride | PVDF | -50 +150 | XXX | XXX | XXX | XXXX |

| Polyetheretherketone | PEEK | -55 +200 | XXX | XXXX | XXXX | XXXX |

| Polyethylene Terephthalate | PET | -55 +125 | XX | XXXXX | XXX | XXXX |

| Fluoropolymer | ECTFE | -50 +135/150 | XX | XXXX | XXXX | XXXX |

| X-Linked Polyethylene | XLPE | -50 +90 | XXXX | XX | XX | XX |

| Silicone Rubber | SI | -100 +180 | XXXX | XXXX | XXXX | XXXX |

| Thermoplastic Rubber | TPR | -60 +135 | XXX | XX | XX | XXX |

KEY:

American wire gauge to circulate mils square millimetres.

AWG = American Wire Gauge

NCSA = Nominal Cross Section Area

ND = Nominal Diameter

mm² = Millimetres Squared

| Size AWG / MCM | Circular MM | NCSA mm² | Solid Wire ND Inches | Solid Wire ND MM |

|---|---|---|---|---|

| 24 | 404. | .204 | .0201 | .51 |

| 22 | 642.4 | .321 | .0253 | .64 |

| 21 | 810.1 | .412 | .0285 | .72 |

| 20 | 1.020 | .52 | .0320 | .81 |

| 19 | 1.290 | .653 | .0359 | .91 |

| 18 | 1.620 | .823 | .0403 | 1.02 |

| 16 | 2.580 | 1.31 | .0508 | 1.29 |

| 14 | 4.110 | 2.08 | .0641 | 1.63 |

| 12 | 6.530 | 3.31 | .0808 | 2.05 |

| 10 | 10.380 | 5.3 | .1019 | 2.59 |

| 9 | 13.090 | 6.6 | .1144 | 2.91 |

| 8 | 16.510 | 8.4 | .1285 | 3.26 |

| 6 | 26.240 | 13.3 | .1620 | 4.12 |

| 4 | 41.740 | 21.15 | .2043 | 5.19 |

| 3 | 52.620 | 26.7 | .2294 | 5.83 |

| 2 | 66.630 | 33.6 | .2576 | 6.54 |

| 1 | 83.690 | 42.4 | .2893 | 7.35 |

| 1/0 | 105.600 | 53.5 | .3249 | 8.25 |

| 2/0 | 133.100 | 67.4 | .3648 | 9.27 |

| 3/0 | 167.800 | 85.0 | .4096 | 10.40 |

| 4/0 | 211.600 | 107.2 | .4600 | 11.68 |